Research

The research that the institutes of the KIT Department of Chemical and Process Engineering conduct plays an important role in sharpening KIT's profile in the socially relevant areas energy, mobility and information. The nationally and internationally renowned research of the KIT Department covers process engineering issues from scientific bases to technical applications and from laboratory experiments to pilot plants.

Main areas of research are:

- Development of processes and methods for closing material and energy cycles as the basis of a sustainable society (circular economy)

- Synthesis of chemical energy sources from ubiquitous materials and renewable energy

- Development of innovative, resource-saving process engineering and biotechnological processes for the processing of raw materials of biological origin into biopharmaceuticals, foods, fine chemicals and basic materials for the chemical industry

- Development of processes for water reuse

- Development and use of digital tools for bioengineering and chemical engineering

The researchers of the department lead and coordinate national and international research projects (DFG, BMBF, EU, ...) and contribute significantly to the research programs of the Helmholtz Association.

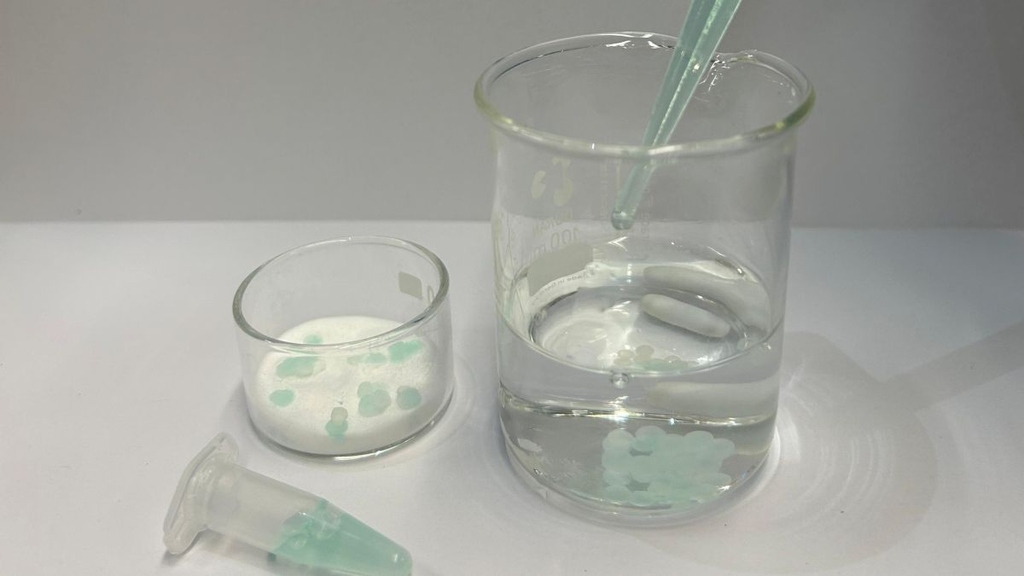

The RTG, which will be funded from October 2025, focuses on sustainable hydrogels, which are important in many life science applications such as food science and pharmacy due to their biocompatibility. Synthetic polymers could be replaced by sustainable polysaccharides from land plants and algae, but this leads to different gel properties. The RTG “Sustainable hydrogels: From chemical structures to applicability” looks at the entire life cycle of these hydrogels, from formation to ageing.

More

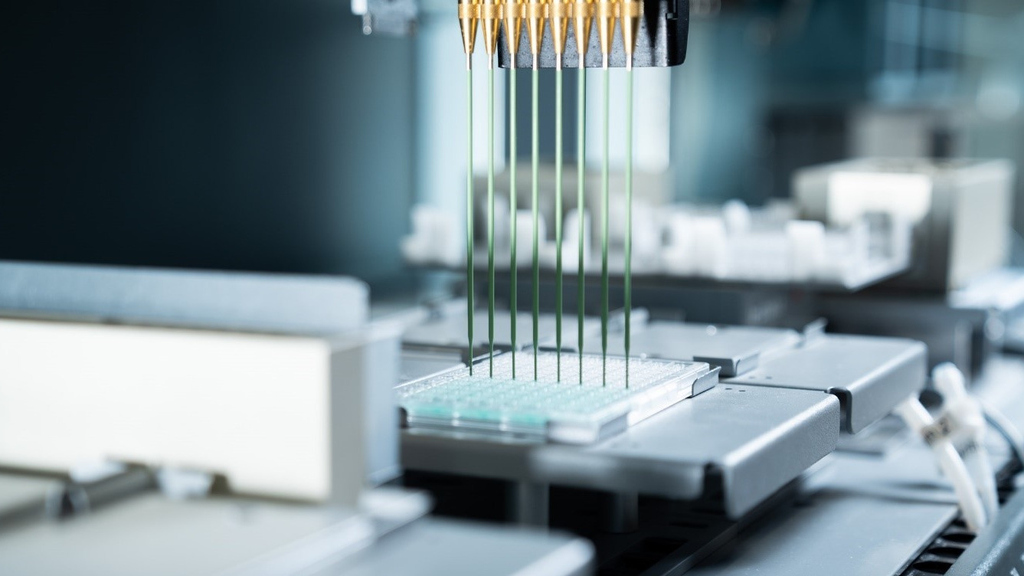

Greater efficiency, speed and precision in laboratory analyses as well as drastically reduced material consumption: with the SpecPlate, the spin-off PHABIOC from the Karlsruhe Institute of Technology (KIT) is replacing up to four conventional sample carriers with an innovative design. Series production is now starting.

More Information

The bioliq® plant at the Karlsruhe Institute of Technology (KIT) can produce a synthesis gas from carbon monoxide, carbon dioxide and hydrogen, among other things, from residues from agriculture and forestry. KIT researchers have now succeeded for the first time in producing methane from this, which, after appropriate processing, could be fed directly into the German natural gas grid and replace fossil gas. In the three-phase methanisation process used for this purpose, a catalyst is suspended in a liquid. This is located in a bubble column reactor through which the synthesis gas flows.

More Information

Extracting the greenhouse gas CO2 from the atmosphere and converting it into a stable carbon through combined processes - this is what a new plant network at the Karlsruhe Institute of Technology (KIT) has been doing this month. The process, developed in the NECOC research project together with industrial partners, combines negative emissions with the production of a high-tech raw material. Now it is to be optimised in terms of energy and scaled up.

More Information